0755-27662758

sales@hiphotonics.com

Hiphotonics makes optoelectronic composite cables that offer a lot of benefits that make them a popular choice.

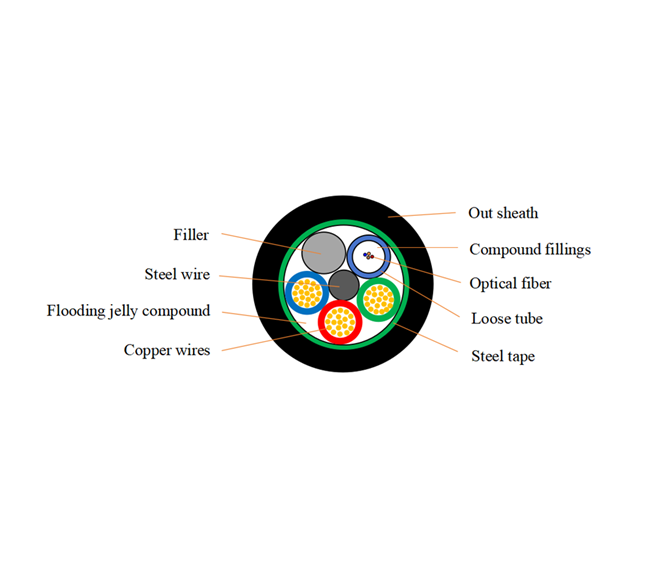

Opto-electric composite cable combines the best parts of optical fiber and cable to send both optical and electrical signals at high speeds. The optical fiber part lets data move quickly and with a lot of bandwidth, and the cable part lets power be transferred and equipment be powered to meet a wide range of application needs.

Save space and money: The design of optical and electrical composite cables saves space and lowers the cost of materials and installation compared to separate wire. This makes it great for places where space and money are restricted, such data centers and smart buildings.

High reliability and stability: Hiphotonics closely monitors the manufacturing process to make sure that the quality and performance of optoelectronic composite cables are always the same. They can work for a long time under harsh conditions, which guarantees that network connections will stay up and running.

Adaptability and customization: Optoelectronic composite cables can be made to meet the particular needs of customers, including length, specifications, and types of interfaces. It can be used in many different situations and can meet the needs of different projects because it is so flexible.

Sustainability and protecting the environment: Hiphotonics is dedicated to making products that are good for the environment. Optoelectronic composite cables are made from materials that may be used again and again and in ways that are good for the environment. They also follow the idea of sustainable development.

|

Item |

Unit |

Specification |

|

|

Fiber Type |

G.652D |

||

|

Mode field diameter |

1310nm |

mm |

9.2±0.4 |

|

1550nm |

mm |

10.4±0.8 |

|

|

Cladding diameter |

mm |

125.0±1 |

|

|

Cladding non circularity |

% |

£1.0 |

|

|

Core/cladding concentricity error |

mm |

£0.5 |

|

|

Coating diameter |

mm |

245±10 |

|

|

Coating non Circularity |

% |

£6.0 |

|

|

Coating/cladding concentricity error |

mm |

£12.0 |

|

|

Cable cut-off wavelength |

nm |

£1260 |

|

|

Zero Dispersion Wavelength |

nm |

1300 ~ 1324 |

|

|

Zero Dispersion Slope |

ps/(nm2·km) |

≤0.092 |

|

|

Chromatic Dispersion |

1288 ~ 1339 |

ps/(nm. km) |

≤3.5 |

|

1550 |

ps/(nm. km) |

≤18 |

|

|

1625 |

ps/(nm. km) |

≤22 |

|

|

Attenuation Coefficient |

1310nm |

dB/km |

£0.36 |

|

1550nm |

dB/km |

£0.22 |

|

|

1383nm |

dB/km |

£0.35 |

|

|

1625nm |

dB/km |

£0.30 |

|

|

Proof stress level |

kpsi |

≥100 |

|

|

Item |

Parameters |

|

|

Fiber Count |

4 |

|

|

Colored coated fiber |

Dimension |

250µm±15µm |

|

Color |

Blue、Orange、Green、Brown |

|

|

Loose tube |

Dimension |

1.9mm±0.2mm |

|

Material |

PBT |

|

|

Color |

Blue |

|

|

Central Strength member |

Dimension |

1.5mm±0.1mm |

|

Material |

Phosphating steel wire |

|

|

Copper wires 2.5 |

Dimension |

4.5mm±0.4mm |

|

Material |

PVC/LSZH |

|

|

Color |

Red、Blue、Green |

|

|

Armoured |

Material |

Plastic coated steel strip |

|

Outer jacket |

Dimension |

11.8mm±0.3mm |

|

Material |

MDPE |

|

|

Color |

Black |

|

|

Conductor cross-sectional area |

(20℃)(Ω/km) The biggest single conductor dc resistance(20℃)(Ω/km) |

(20℃)(MΩ.km Insulation resistance(20℃)(MΩ.km |

Insulation compressive strength KV,DC1minutes |

||

|

Every insulated wire and cable connected between the other metal |

Wires between |

Wire and gold With a sheathed |

Wire and Between the wire |

||

|

2.5 |

7.98 |

Not less than10000 |

5 |

5 |

3 |

|

Conductor cross-sectional area |

(20℃)(Ω/km) The biggest single conductor dc resistance(20℃)(Ω/km) |

(20℃)(MΩ.km Insulation resistance(20℃)(MΩ.km |

Insulation compressive strength KV,DC1minutes |

||

|

Every insulated wire and cable connected between the other metal |

Wires between |

Wire and gold With a sheathed |

Wire and Between the wire |

||

|

2.5 |

7.98 |

Not less than10000 |

5 |

5 |

3 |

|

S/N |

Item |

Standard |

Specification |

|

1 |

Tensile strength

|

IEC 60794-1-2 Method E1

|

-Short term tension:≥0.5G -Long term tension:≥0.15G -G=1km weight: N |

|

2 |

Crush |

IEC 60794-1-2 Method E3

|

-Long term:150N -Short term:450N |

|

3 |

Repeat bending |

IEC 60794-1-2 Method E6IEC |

-Loading 25N;25cycles |

|

4 |

Twisted |

IEC 60794-1-2 Method E7 |

-Loading 40N;5 cycles |

|

5 |

Water penetration |

IEC 60794-1-2 Method F5 |

1m water column, 3m cable sample, 24hours |

|

6 |

Blowing Performance |

IEC 60794-5 |

- Additional attenuation is less than after air blowing |

Wechat/WhatsApp: +86 130 7568 1698

Tel: +86 0755-27662758

E-mail: sales@hiphotonics.com

Add:D6 Building, Chuangzhao Industrial Park, Kengzi Street, Pingshan District,Shenzhen,China